Quality Control

Quality control is a very important task in our JCON Technology Co., Ltd.

We look very seriously at the quality of our products and are committed to providing our customers with the highest quality products and services. We will continue to strengthen quality control and continuously improve product quality to meet customer needs and expectations. We ensure product quality through the following key stages:

1. Raw Material Incoming Control: We conduct strict inspections on all incoming raw materials to ensure that their quality meets our requirements. We have a dedicated team that checks the raw material specifications, quality standards and other necessary requirements. In addition, we conduct chemical and physical testing to ensure the stability and consistency of the ingredients.

2. Production Process Control: During the production process, we use advanced production processes and equipment to ensure the consistency and reliability of product quality. At the same time, we will also conduct quality spot checks on semi-finished products to prevent quality problems. In addition, our operators and inspectors have undergone strict training to ensure that they understand the requirements of the product and how to operate according to the standards.

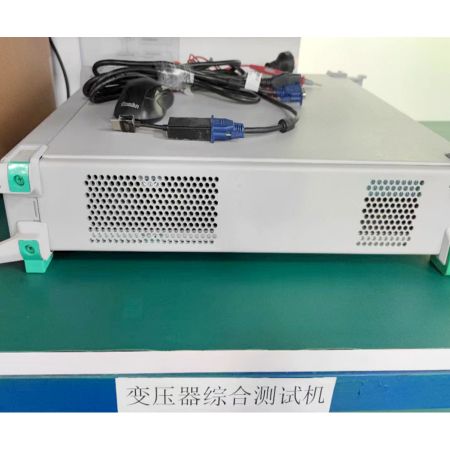

3. Finished Product Inspection: After product production is completed, we conduct comprehensive quality inspections to ensure that the products meet our strict requirements. We check the appearance, dimensions, functionality and other relevant characteristics of the product. In addition, we conduct a series of tests and inspections to ensure that product performance and quality meet all customer requirements.

4. Compliant Inspection Conditions: Our products need to comply with standards including: ISO 9001, RoHS, REACH, FCC Part 68, EIA-364, etc. Our inspection team will test and inspect products against these standards to ensure our products meet all relevant requirements.

5. NG Products Process: If NG products are found, we will immediately identify, quarantine and dispose of them. We will take appropriate measures based on the nature of the NG products. At the same time, we will also analyze the causes of NG products and correct them to prevent similar problems from happening again.